■ AUTOMATIC BATCHING SYSTEM

■ RUBBER KNEADER

■ RUBBER MIXING MILL

■ BATCH OFF MACHINE

BORIA - Rubber Machinery

Qingdao Boria Machinery Manufacturing Co., Ltd is an integrated manufacturer of design,production and sales.which has more than 25 years of experience in this rubber machinery field,can guarantee to provide users with more perfect services.

Boria main products including:

● Rubber Compound Production Line:Auto Weighing System;Hydraulic Cutter;Kneader;Rubber Mixing Mill;Batch Off Cooler

● All Types of Rubber Vulcanizing Press;EVA Foaming Machine;etc.

● Extrusion Line

● Conveyor Belt Production Machine :Conveyor Belt Building Machine;Belt Vulcanizing Machine;Belt Winding Machine;Belt Splicing Machine.

● Tyre Recycling Line :Rubber Powder Production Line;Tyre Cold Retreading Equipment

● Other Auxiliary Equipment:Cloth Finishing Machine;Industrial Intelligent Automatic Machine,etc

We can also customize the machines according to the customer’s needs!

4000

Plant size

39

Number Of Employees

2016

Year of establishment

5

Production Line

2

Production Base

Experience Advantage

Qingdao Boria Machinery Manufacturing Co., LTD changed officially its name from a state-owned machinery company in October 2007, is a professional manufacturer in rubber machine field of China with high-tech technology.

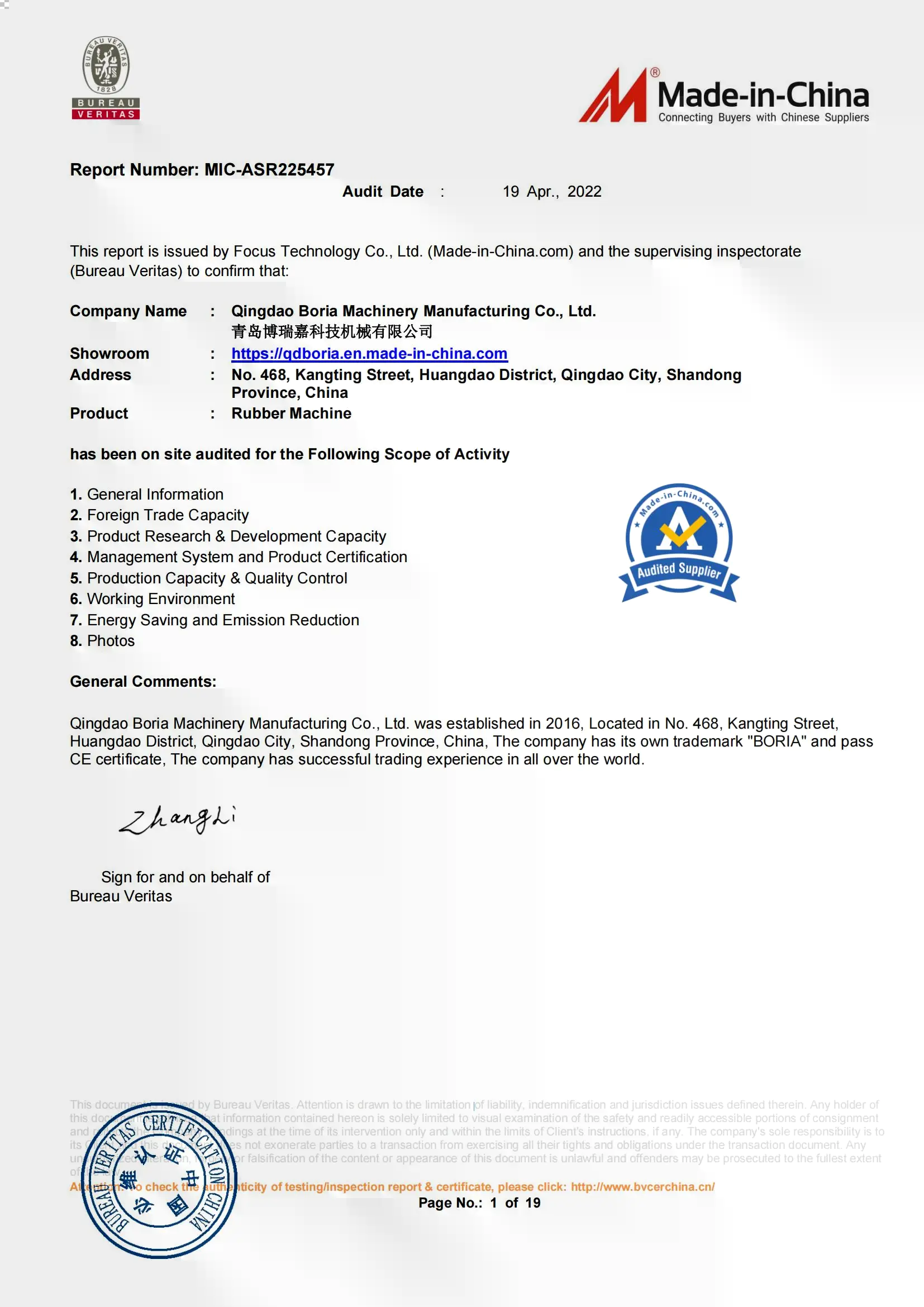

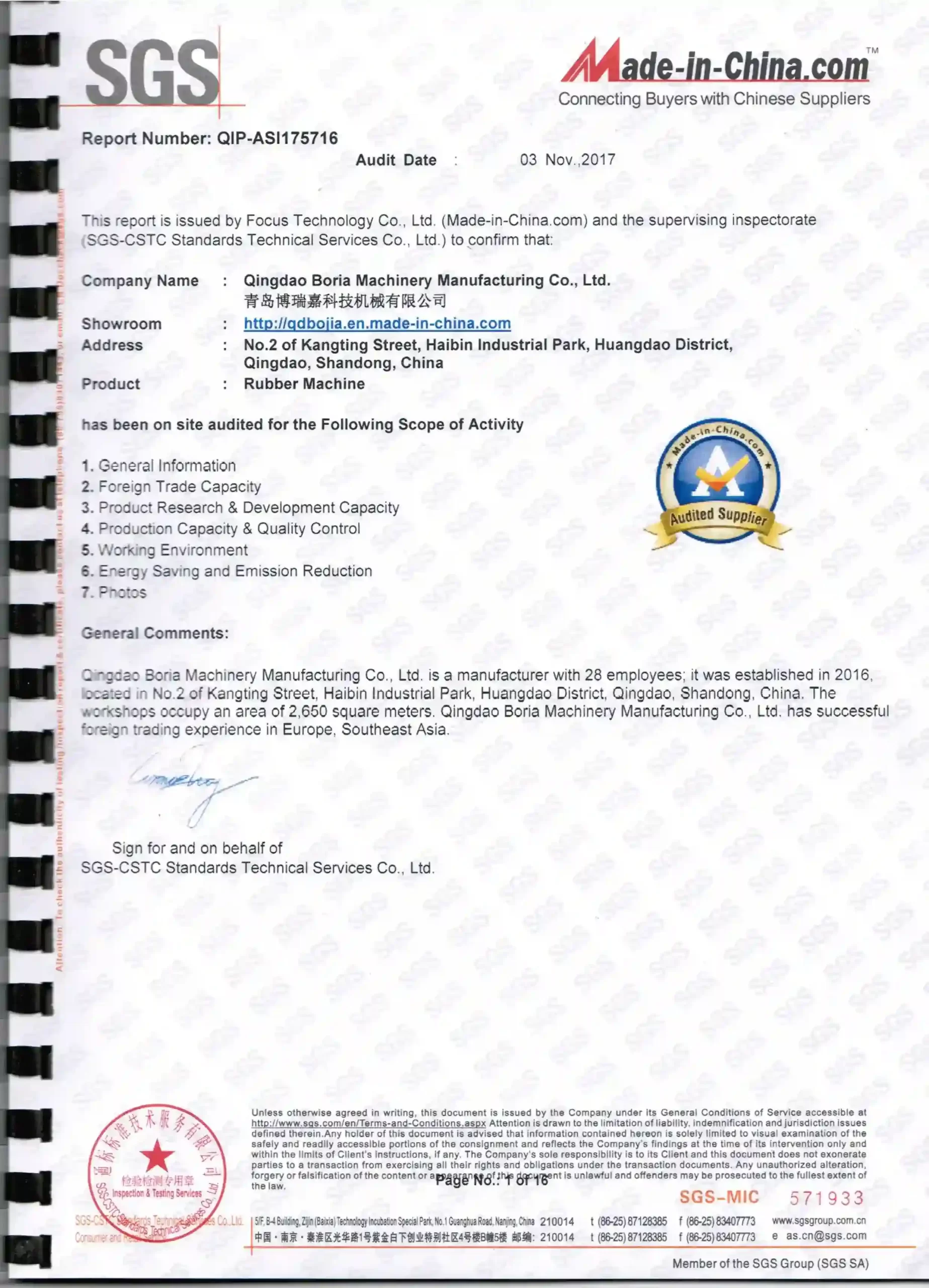

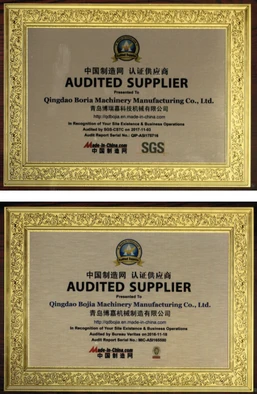

We have ISO9001: 2008, BV. And if you need other certifications, we will make it for you according to your requirements. Our customers spread all over the world, such as the United States, Germany, Mexico, Colombia, Canada, Singapore, Malaysia, Australia, Korea, Japan, India, Russia etc.

There’s experienced engineers and outstanding technical teams in our factory. We could make a professional design specially for you. We often communicate with the customers and technology authority departments of rubber industry, constantly to improve and update our products which could meet the requirements of the customers. And we also could design and manufacture various non-standard products according to users requirements.

Product Categories

Two Rollers Open Mixing Mill, Rubber Mixing Mill

75/125/180/250L Rubber Kneader, Rubber Banbury Mixer, Dispersion Kneader Mixer

Batch off Cooler/Rubber Sheet Cooling Machine/Rubber Products Cooler Machine

Plate Frame Rubber Mat/Rubber Plate Hydraulic Vulcanizing Press

Batching System with Fully Automatic Control/Automatic Weighing System

Cold Feed Rubber Extruder , EPDM Rubber Strip Production Line

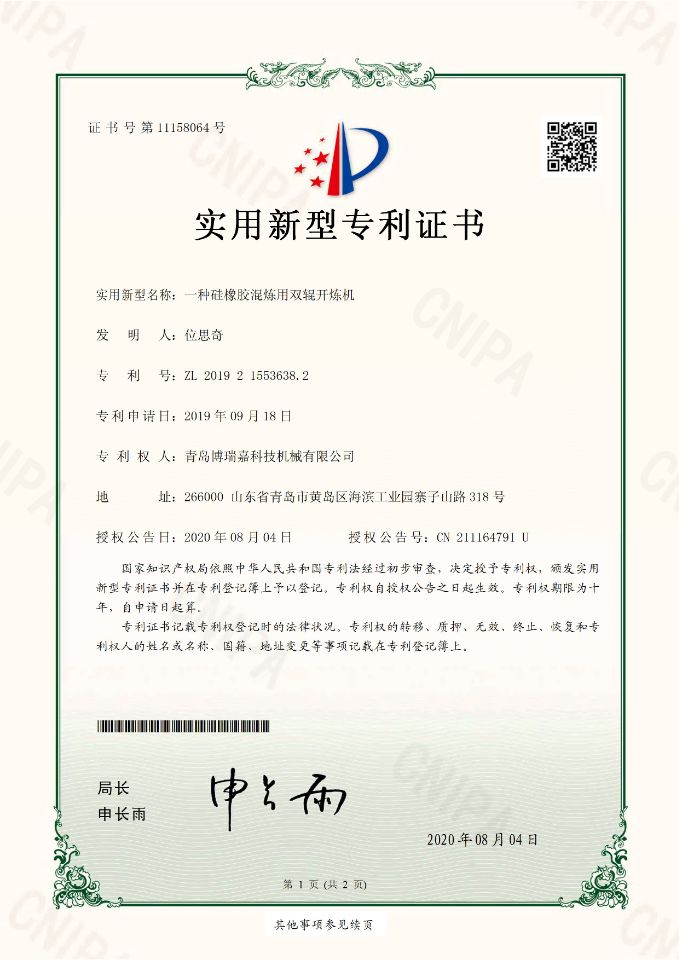

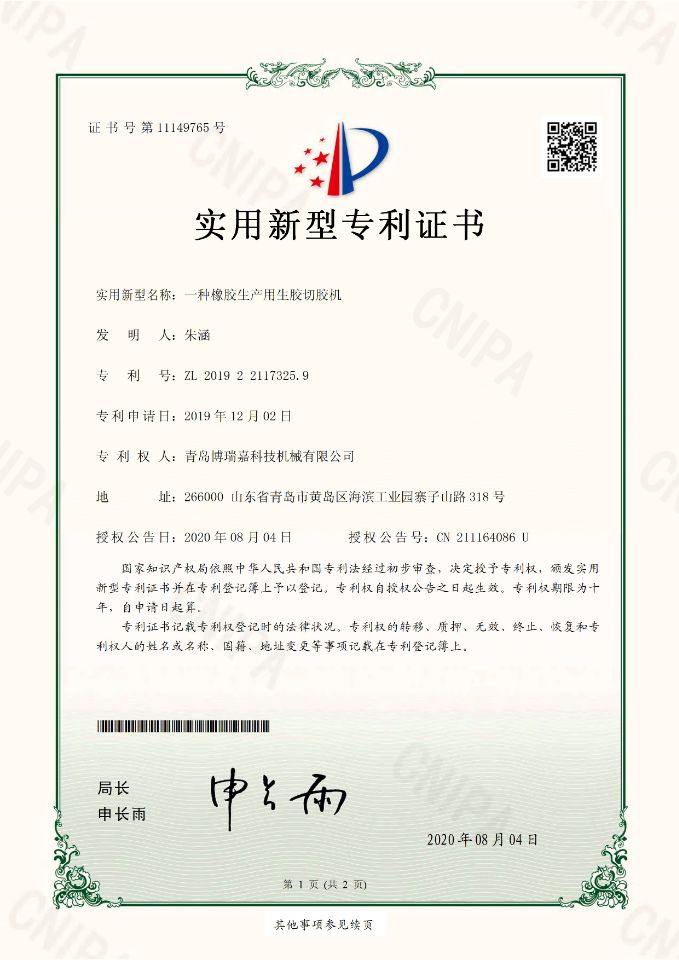

Certificate Qualification

Factory Environment

Service Guarantee

1. Test running: The above machines are all passed inspection of 3~5 hours of full load operation before leaving our factory. And we will take the video and send it to you for inspection. You can use it directly thus saving the time of test-run and expense. And we also warmly welcome to our factory to inspect and test running.

2.Warranty: 12 months after installation, if our machines have any problems, please feel free to contact me. We will solve it for you as soon as possible, and give you the best services.

♦ We could supply free English foundation DWG, installation drawing, user guide, maintenance manual and part drawing.

♦ We supply overseas engineer service and help to train your workers to operate the machine.

Help FAQ

This is specially designed machine according to your specific requirement.

From engineer designing to production completion, it needs about 25 to 35 days.

we have a professional development team that can make new products according to your requirements.

Common is 30% deposit by T/T, the balance paid before deliver.

Our factory located in Qingdao city. You can fly to QINGDAO JIAODONG airport, then we can pick you up to our factory for your visiting. We are looking forward to your visiting.

Our Latest Blog

BORIA Machinery: Leading the innovation of rubber machinery manufacturing

Boria Machinery is an enterprise committed to rubber machinery manufacturing industry. They lead the development of the entire industry and continuously improve the production efficiency

Safety precautions when operating open mill

Safety precautions when operating open mill Open mixer is one of the main equipment of rubber factory. The operation of rubber smelting is an accident-prone

Rubber film batch-off machine process

Rubber film/sheet batch-off machine process: 1. The rubber from the extruder in the internal mixing workshop first enters the front discharge device of the film