USE:

Rubber Mixer is mainly used in Rubber & Plastic Product factory for Natural Rubber Mixing(plasticating), Raw Rubber and Compound mixing, rubber warm-up mixing and pressing sheet.

Structure description:

Materials of Rolls: The roller are made of chilled cast iron alloy (LTGH), whose surface is 78HS, after quenching and precision processing it is harder than other company,(they are usually 72HS ) .The working surface is well grinded and machined.temperature uniformity in smooth surface, high hardness and long working life.

Motor: We always use OMRON,SIMENS ect brand electric parts or you can choice the ordinary brand. All the motor is high quality and effiency, save energy, low noise, and small vibration.

Roll gap adjustment: Roll nip adjustment is realized by hand or electricity which can obtain high accuracy and sensitivity.

Reducer: The speed reducer is hardened tooth with class 6 precision, no noise and vibration, safety with higher transmission efficiency.(There are a variety of choice, the price is different),Gear Box(double out shaft transmission).

Frame: The base frame is a whole framework and cast iron, which is convenient for installation and easy to maintain.

Stock bender: It for direct rubber sheet and knife to cut as your need to assemble. Then improve the quality of mixing, and reduce the energy consumption.

Emergency brake device:The machine is also equipped with an emergency brake device. When an emergent arises, just draw the safety pull rod or press the emergency button and the machine will stop immediately. It is safe and reliable.The machine is equipped with an overload protection device to prevent the main components from being damaged.

Cooling system: (with rotating joint):Universal rotary joints with inner spray pipes with hoses and headers. Piping is complete up to supply pipe terminal, which reduces energy consumption by 50% and high efficiency.

Auto-lubrication system for grease or oil and match bearing bush.

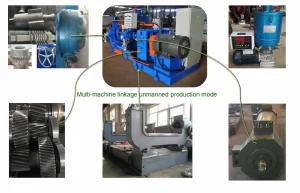

MODALITY:

1.Two roll mxing mill: Connon Gear Type (Nylon shoe, Copper shoe and Bearing).

2.Two roll mixing mill: Reducer use Hard Tooth Face Type.

3.Two roll mixing mill: B type. (The motor under the roller)

4.Two rolll mixing mill: H type.

In addition:

1. Proffessional design team

And our company has a proffessional design team, if you have any requirements, please feel free let me know, we will do our best to meet your needs.

We have ISO9001: 2008, BV. And if you need other certifications, we will make it for you according to your requirements. Our customers spread all over the world, such as the United States, Germany, Mexico, Colombia, Canada, Singapore, Malaysia, Australia, Korea, Japan, India, Russia etc.

2. Lab machines

We had a lot of cooperation with East China University of Technology State Key Laboratory of Chemical Engineering, Qingdao university,Beijing chemical industry research institute ect. and supply the lab rubber machines.

3. Our machines list

Our main products including: Rubber kneader, rubber mixing mill, rubber sheet cooling machine (batch off cooler), all kinds of rubber vulcanizing press machine (semiautomatic and full automatic), rubber extruder, waste tire recycling production line (rubber powder production line and tire retreading equipment) etc. We can also make non-standard equipment according to customer requirements.

4. Best after-sales services

(1) Our company products must pass inspection through 3-7 hours of load test operating before they leave the factory, thus saving customers’ time and expense of equipment commissioning.

(2) We provide one year’s guarantee and once the equipment damage during this time we supply free of charge. In order to save maintenance time and reduce the production cost of the guests, you can contact our DCRC by email, MSN or Skype etc., and we will send professional technical personnel with English translation to you to solve equipment problems.

(3) Our company establishes " customer file" for sold equipment in the form of return visits regularly; Including equipment’s maintenance, troubleshooting and customer feedback.

(4) After-sales service complaints :

Qingdao Boria Machinery Manufacturing Co.,LTD make high quality rubber machine, from materials to producing,we use the good quality material, complete management system, also excellent aftersale service, we hope to beone reliable factory for you! Our company is willing to have friendly cooperation with all the customers and jointly crease the win-win situation. We have high-quality products and excellent after-sales service. Welcome to visit our company!