4 Layers EVA/Rubber sheet flat Foaming Vulcanizing Press for sale

I. Machine Usage:

EVA/PVC/Rubber Flat Foaming Vulanizing Machine used to foaming all kinds of EVA materrial, Including EVA or PVC foam board, Foam sponge rubber soles and also can be widely used to press and form the solid plastic and ornamental products.

II.Performance characteristics:

1、Automatic control, reliable performance,high degree of automation,avoid accidents caused by incorrect operation

2、The process program can be set, and the operator cannot change it without authorization, which can guarantee the quality of the product to the greatest extent and prevent the operator from changing the vulcanization parameters privately.

3、It has the functions of pre-set automatic mold opening, automatic deflation, automatic pressure compensation, automatic timing, automatic mold dropping, etc. The first closing parameters can be set on the touch screen according to the production requirements.

4、The electric heating type uses a digital display temperature controller to control the temperature, which can set the maximum temperature, display the real-time monitoring of the heating plate temperature, and automatically power on and off according to the set temperature value to control the temperature of the heating plate.

5、The auxiliary oil cylinder controls mold clamping and mold opening, which can achieve high-speed mold clamping and instant mold opening. The vulcanization time is set on the touch screen and the real-time time value is displayed. When the time is up, the mold opens automatically and the mold opens simultaneously with sound and light alarm.

6、The plunger falls back with a buffer to prevent gravity impact on the bottom of the cylinder due to the plunger’s rapid fall.

III. Configuration:

1.The machine adopts the advanced PLC control . The working program can be set in the cabinet and machine will work according to this program

2.Most spare parts for hydraulic system are imported from Taiwan

3.Machine body casting is made of FCD 50 ductile cast iron ,which is processed by high tensile strength after aging passivation

4.The machine pillars/ columns are made of medium carbon steel , and its hardness can reach HRC55-58

5.The cartridge heater adopts three stages winding, nichrome wire , non-rusty

6.Oil seal are from Japanese NOK and Sakagmi Brand , it is wear-resisitant ,durable and oil tight

7.Main electrical elements are from Schneider France ,which can stabilize machine performance

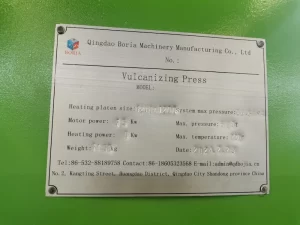

IV. Equipment related photos:

V. FAQ

1.What’s your MOQ?

At present we haven’t strict policy for this, so welcome orders with any quantity.

2.Are you a manufacturer or trade company?

We are a manufacturer. You can assure that we are a producer with full experience doing business in domestic and oversea.

3. We are not professional for operation and installation of your machine?

While it is not a stumbling block, our machine is easy to operate, no need to professional training, and the instruction manual and video sent to you are enough. What’s more, we have professional engineers and they can solve all questions.

4. How about packaging? If machine damaged, what should I do ?

Usually machine is packed with wooden case and standard export carton, plywood carton or as your requirement. Damage haven’t happened before, if happen, we will arrange replacement.

5. We haven’t do business before, how can I trust your company and machine?

We have been GOLD supplier for 3 years with no complaints on Made in China and our machine have exported to many countries and have a good feedback.

6. If I want to visit your factory, is the traffic convenient ?

Our company traffic is very convenient, if you come, we can pick you up in airport.

7. Does your product have CE certification ?

Yes, all our products passed CE certification

8. If there is not any size meet my need, can I customiz ?

Yes, just provide me your detail requirement, we can do as yours.