Product Description:

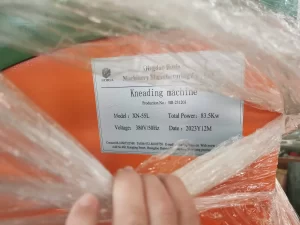

Version: X(S)N-35, X(S)N-55, X(S)N-75, X(S)N-110

Certificate: National Standard/CE/ISO9001/SGS

1. The Banbury Kneader / Disperation Kneader is mainly used for plasticizing and mixing of natural rubber, synthetic rubber, reclaimed rubber and plastics, foaming plastics, and used in mixing of various the degree materials.

2. The rotor adopts rolling bearing for support, so the maintenance work is convenient and the service life is long.rotor shaft of the machine adopt Taiwan technology, rotor ribbed spiral angle and working length of resonable design, can make the material to obtain the best effect of kneading, and faster than ordinary milling machine refinded material 1-2 minutes per session, the rotor edge peak and end face for surfacing welding wear-resisting carbide, rotor and mixing chamber pressure lead, direct contact with the material of surface are after throwing grinding hard chromium plating(0.1mm) as bright as mirror and wear-resisting corrosion resistance. Rotor outside contact pressure type non-lubricated seal structure, the sealing ring is made of high quality copper manufacturer wear-resisting good sealing effect.

3. The transmission device adopts NGW hard tooth flank planet reducer, which has compact structure, low noise and high efficiency. It furnished with reasonable designing, construction tightly packed, occupying small area, installing convenience, highly efficiency of production, operation simply.

4. The Banbury Kneader / Disperation Kneader is the advanced new type mixer equipment of rubber and plastics industry, various features are so advanced as the same product of foreign. For seal designing, we get excellent result in sealing and everlasting

5.Mixing chamber and top of the frame joint that hang a wall, use arc board slot labyrinth seal structure, seal dustproof effect is good. Electric control system use the south Korea import LS electrical components, effectively reduce the incidence of the failure, a perfect and reliable.

Characters:

1. Rotor wings are welded by hard chrome and carbide alloy.

2. Abrasion proof and corrosion resistant.

3. Rubber stock are discharged by tilting 140 degrees.

4. High efficiency, energy saving and saving occupied space.

5. Imported brand PLC control ensure good performance.

6. Interlock protection ensure low personal injury.

7. Our machines have CE certificate.

FAQ:

1.WHY CHOOSE US?

(1) More than 25 years of history in producing compounding and granulating machines for plasticand rubber industries. 6-8 years of foreign sales experience staff, more efficient and professional. Engineers oversea service more than 10 countries.

(2) ISO: 9001, CE certificate.

(3) Serve timely. Promise to give solution within 24 hours.

(4) Short delivery date, No delay. Accept an urgent order for prompt shipment.

2. What does your factory do regarding quality control?

We pay much more attention to the quality controlling from the very beginning to the end of production.

Every machine will be fully assembled and carefully tested before shipment.

3. What’s the machine quality guarantee?

we provide one year warrenty for our machines.We choose the world’s famous brand of components to keep our machine in perfect working condition.

4. Are you able to provide the installation and commissioning of machines overseas? How long will it take?

Yes, we can supply overseas service and technical support but customer needs to pay for the cost of the installation.

Small machine usually takes within 2~3 days.Big equipmwnt usually takes about 30 days.

5. How can I trust you to deliver the right machine as I ordered?

We will absolutely deliver a good quality machine as we discussed and confirmed in the order.

The core of our company culture is innovation, quality, integrity and efficiency. Also we have had much good cooperation with world famous rubber production manufacturers. If you come to our factory, we can show you’re the user around us.

6.What if there is a problem after receiving the device?

perform 24-hour service; determine the cause of the failure through photos or videos within 2 hours, and notify the buyer of the operation method to solve the problem through video or email photos