Product Description:

Automatic Rubber Flooring Tile Vulcanizing Machine, Tile Vulcanizing Machine

1. This vulcanizing press is specially used to produce rubber tiles.

2. Each layer of the vulcanizing press matched with two sets of moulds, so it can be vulcanized batch by batch for better efficiency.

3. The tile vulcanizing press is adopted with manual mould push-out device, so the operation is more convenient.

4.This machine consists of main machine , electrical cabinet ,hydraulic station , eight set adjustable rail device , etc .

5.It has four working layers . It is widely used to produce various kinds of rubber flooring tiles , bricks , pavers and other products together with rubber mixer machine and mold

Details:

1, We usually design as clients’ products and details request. our machine is 4 working layers , 1 hour can made 8 pcs rubber floor. We can also according your needs. and decide the working layers.

2.The machine is matched with manual push-out device .(If the customer needs, this model has the function to eject the tile from mold automatically)

3, We also can provide the different size of the moulds, from 20mm to 75mm thickness.

4, Rubber mixer can also provided, if needed.

5, The press with 12 pcs mould and rubber mixer is only 8m3 of the flooring area, it can be LCL for loading, So the sea freight is very cheap.

Configuration:

1.The machine adopts the advanced PLC control . The working program can be set in the cabinet and machine will work according to this program

2.Most spare parts for hydraulic system are imported from Taiwan

3.Machine body casting is made of FCD 50 ductile cast iron ,which is processed by high tensile strength after aging passivation

4.The machine pillars/ columns are made of medium carbon steel , and its hardness can reach HRC55-58

5.The cartridge heater adopts three stages winding, nichrome wire , non-rusty

6.Oil seal are from Japanese NOK and Sakagmi Brand , it is wear-resisitant ,durable and oil tight

7.Main electrical elements are from France ,which can stabilize machine performance

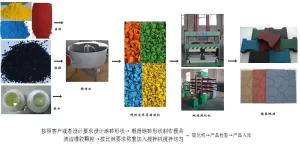

Production flow chart

1. Conching

Put the rubber granulates and stain into the stirring barrel to stir, and then put into the adhesive to stir. This process requires for 4-6 minutes ( because the adhesive is easy to cure, so stir it when use ).

2. Weighing raw materials

Weight the rubber granulates stirred, according to the granulates’ thickness requirement of the tiles.

3. Paving and pressing

Paving the rubber granulates weighted on the mold, then floated it by trowel. Firstly paving the surface rubber granulates which is fine and color, then the thickness and black.

4. Vulcanization molding

Covering anti adhesion cloth, pushing the mold into vulcanizer to vulcanize, the time of vulcanization accord to the thickness of the rubber tiles, in general, 3-8inutes finished. After that, Mold separate automatic, then remove floor tile on the shelves to dry.

5. Inspecting

Inspect the surface of the floor tiles formity, no aberration, no flaw, line with the product quality.

Rubber machine.

Good quality with reasonable price. Easy operation with convenient maintenance. Low labor intensity and low energy consumption.

Rubber sheet-rubber mat-rubber tile vulcanizing press to make good quality rubber sheet, rubber tile and rubber mat.

Operate stable, can produce rubber sheet, rubber tile and rubber mat efficiently.

Certificate:

Qingdao BORIA Machinery Co., Ltd is the professional manufacturer of various tile vulcanizing press. Our company has passed ISO9001: 2008 Quality Management System Certification ,BV Certificate and our products have qualified with Sweden SGS Certificate, and CE Certificate.

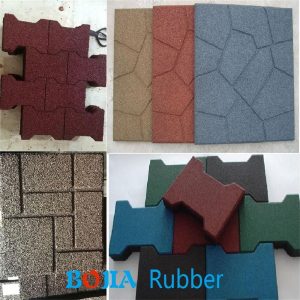

Floor tiles related knowledge

Features:

1、Light weight

2、The particles are clean without glue powder adsorption;

3、Good stretch and elasticity;

4、Strong adhesion between particles and PU glue, not easy to thresh;

5、Abrasion resistance is not easy to age, and always keep it as clean as new;

6、Good weather resistance, the production process is less affected by temperature, and can be used all day.

7、Rubber particles:

7.1 The rubber particles are triangular rhombuses, which can enhance the structural stability after laying, and avoid the shortcomings of long flat and spheroid particles.

7.2 The granular material is excellent, has good elasticity, is clean, and has strong adhesiveness. Black rubber particles and colored rubber particles for artificial turf are suitable for mixed floor tiles, playgrounds, kindergartens,etc.

7.3 The proportion of various materials in the floor tile (by weight) is 4-10% glue (binder); 1-5% dyeing agent; 85-95% rubber particles.

Our Company Serivice:

1. One-year guarranty.

2. If quality problems happen within guarantee period, our company will repair for free.

3. 100% test and adjust the machine before delivery, and production pictures will be sent to clients, to help them know the machines better.

4. Additionally, our company provides technical support and fittings for life.

5. After-sales service is available any time.

6. If needed, our technician is available overseas to help you.