Product Description:

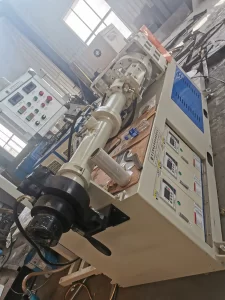

Rubber Extrusion Line, EPDM Seals Production Line, EPDM rubber strip production line SJ-75

I. Usage: It applies to extrude and vulcanize various seals, EPDM, butyronitrile seals and so on.

II. EPDM rubber seals production line producing process: Raw materials -Internal Mixer – Rubber Mixing Mill – Extruder – Vulcanizing Box – Cooling Traction – Packaging and Storage.

The cold feel rubber extruder using forced feeding rollers which operating system design at the nearest workspace, humanized design will largely reduce the labor intensity of workers.

we are specilize in rubber extrusion machine and vulcanization machine for rubber sealing profile , rubber hose, silicon rubber profile, butyle rubber tape and sheet product, insulation rubber sheet and pipe products More information please contact us freely.

III. The features of this line: Uniform vulcanization, quick vulcanizing speed, high efficiency, high product quality, low production costs, environmental protection and energy saving.

1. Qingdao Boria Machinery Manufacturing Co.,LTD has passed ISO9001: 2008 Quality Management System Certification and our products have qualified with Sweden SGS Certificate and CE Certificate.

2. Cold feed extruder using the overall welding of base, compact structure, safety, reliable, convenient and quick installation and commissioning.

2.1 Gear Reducer adopts the rectangle hardened reducer. Gears using high-quality high-strength low carbon alloy steel of 6 grade transmission accuracy, the tooth surface carburizing quenching and tooth grinding. With low noise, long service life and strong bearing capability.

2.2 Screw is the core component of extruder; Material is 38CrMoALA, after nitriding treatment, with wear-resistant, long life and high strength which can withstand high torque and high speed.

Our company has made unique design to the screw thread structure according to the clients’ rubber seal technology requirements, which divided into sub-fast feeding, slow progress, mixing and other five phases.

2.3 Barrel is using cold, hot water circulation adjustment pumps or mold temperature device to adjust the temperature.

2.4 Motor with inverter control and adjustable speed.

2.5 Base: Steel plate welded structure, eliminating internal stress after annealing then machining.

3. Automatic thermostat circulating vulcanizing box is the vulcanization device of rubber seals. Appearance requirements: Smooth and tidy.

(1) This rubber cold feed extruder is used to electricity heating tube automatic thermostat which temperature control accuracy of +/-2° C, the temperature range at room temperature to 260 degrees.

(2) Effective length of vulcanization box is 24m, centrifugal fan circulation. It liner with 120stainless steel and the middle insulating layer is fully filled with aluminum silicate cotton.

(3) Vulcanization box is divided into three zones, each zone with trimmer potentiometer which adjusts the speed of the three zones of vulcanizing box to equilibrium; In the middle of each zone with the ventilating device, and removing the emissions generated by the vulcanization process in time in order to ensure the smoothness of the rubber products.

4. The entire production line speed is adjustable to match with speed of the extruder.

IV. Our Related photos:

V. FAQ:

Q:How many days do you need to produce this machine?

A: Usually 35-40 days,it depends on the machine and power mode,

customized type will be 40-45 days,for production line equipments will take 2-3 moths.

Q: What’s your machine quality guarantee?

A:Usually it’s one year. We will choose the world famous brand components to keep our machine in perfect working condition.

Q:Where can we get spare part?

A: we choose International Brand that customer can find it in everywhere, such as Siemens, Omron, Delixi etc, or send parts by DHL, Fedex, TNT and other express.

Q: How many year’s experience does your company have?

A: More than 25 years of concentration, we mastered several key technologies.

Q: What product can you supply?

A: Rubber press machine, Vacuum molding press machine, Injection Molding machine, Rubber mixer machine, calender machine, extruder machine and rubber product equipment solvtions.