Rubber Floor Tile Making Machine /Mat Vulcanizing Press with ISO certificate

I. Introduction:

This production unit is to produce floor tiles by using rubber granules that have been washed and processed from waste rubber products. Rubber particles from old rubber tires, conveyor belts, etc,After dust removal, the glue, rubber particles, and dye are weighed according to the requirements of the process and added to the blender and stirred well,Load the mixed raw materials into the mold again according to the set weight of each floor tile,The vulcanizing machine is heated under pressure and then vulcanized.,A product production process is completed。A curing machine according to the size of the hot plate and the size of the product,Several products can be produced simultaneously in a single vulcanization process.

II. Characteristic:

1. Light specific gravity;

2. No powder particles clean adsorption;

3. Stretch and good elasticity;

4. Particles and strong PU glue adhesive performance not easy threshing;

5. Wear-resisting not easy ageing, keep clean as new;

6. Good weather resistance, small production process affected by temperature, can be all-weather use.

III. Main feature :

1.The equipment is a special former designed to produced colorized rubber tiles .

2. It can control temperature automatically , auto auxiliary pressure ,alarm at fixed time , and it is of little noise , low vibration , no leakage ,easy operation and little floor area

3.A former is composed of main engine , an electrical control panel and hydraulic station . The complete machine is designed integratively , it is easy to install and maintain , the operation is convenient , and the running is safe .

4.we can complete heating , molding and solidifying at the time , the finished goods can be produced between 8 and 10 minutes

5.The mold adopts the automatic adjustable rail device to push and pull , the efficiency is very high , and labor intensity can be reduced . we can produce tiles with different thickness by one mold.

6.High speed open/close molds, high production efficiency.

7.Automatic in/out mold and ejector device, low labor strength.

8.Optional normal valve or proportional valve, advanced oil way matching, reduce energy consumption.

9.The electric system adopt PLC programming control, which is easy to be operated.

10.Simple and convenient structure, flexible operation, commodious space. The cylinder and plunger are made up of high quality materials

11.Hydraulic station and electric cabinet are Located in both sides of the main engine

We can also design and produce according to customer’s requirement. If you are interested in our products or have any questions, please contact us freely. We will try our best to meet your requirement in the first time.

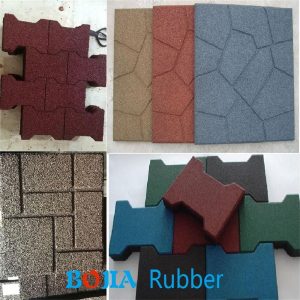

IV. Related Photos:

V. FAQ

1.Are your company a trading one or a factory?

Factory + trade (integration), 25 years focusing on rubber machine design and production .

OEM is also acceptable for us.

2.How to choose the most suitable products?

Our professional team will give you the best suggestion as long as you tell us what kind of product you need to do and the required specification.

3.Do you accept customization service?

Yes, of course, we can not only offer standard machines, but also customized machines according to your request. Don’t hesitate to tell us your requirement, we will try our best to meet your needs.

4.How about your warranty?

Generally, our warranty is one year. Within the warranty period, we can offer technique support and part parts change,

necessarily, our engineers may go to your place for better service.

5.How about the packing for machine, is it safely protected during transportation?

Our machine is packed by standard export wooden box, it won’t be damaged. We’ve delivered many testing machines abroad by sea or by air without damage.

6.What is the order process?

Inquiry – quotation – communication – order confirming – deposit payment – production – testing and debugging – balance payment -packing – delivery – customer receiving – after service.